AGV Reference Platform

Manufacturing

Automation

Drive & Control

We developed a revolutionary low-cost AGV platform for spinning mills, achieving:

- Under $80,000 total budget for complete AGV system

- 80kg payload capacity for transporting textile manufacturing products (yarns, bobbins, and sliver cans) up to 1200mm height

- Modular design supporting interchangeable platforms and future enhancements

- Dust-resistant construction optimized for fiber-dense textile environments

Project Vision

The vision was to revolutionize material handling within spinning mills through development of a cost-effective, modular, and scalable under-carriage Automated Guided Vehicle (AGV). This AGV serves as a modular robot platform with potential for future enhancements, including robotic arms and specialized tools.

The AGV streamlines transport of materials such as yarn, bobbins, and sliver cans between processing stations, improving operational efficiency and reducing manual labor in textile manufacturing environments.

Technical Approach

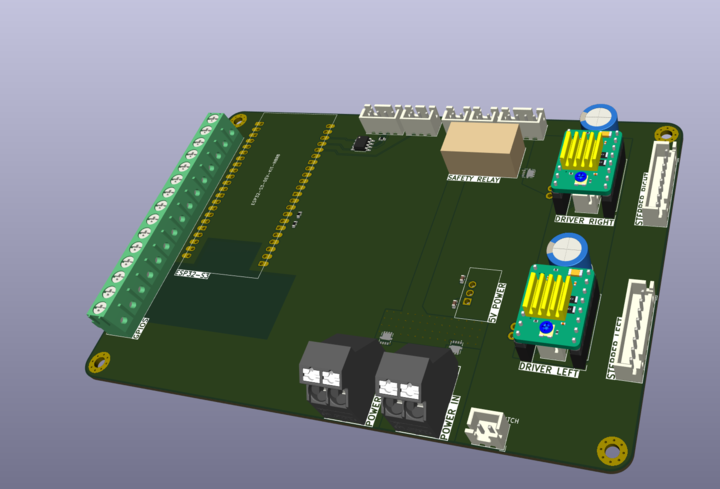

System Architecture

| Component | Specification | Details |

|---|---|---|

| Base Dimensions | 600mm × 800mm | Accommodates 600mm diameter sliver cans |

| Drive System | Differential drive + caster wheels | 2x stepper motors for precise control |

| Payload Capacity | 80kg maximum | Handles cans up to 1200mm height |

| Navigation | Line following / magnetic tape | IR/camera-based sensors with ±5mm accuracy |

| Power System | 24V/48V LiFePO4 battery | 2-6 hours runtime per charge |

| Control Platform | ARM-based IPC with Linux/ROS | Modular software architecture |

Modular Platform Design

Despite the cost, the AGV features a sophisticated modular system designed for rare but necessary component swaps:

Mechanical Interface

- Docking plate with quick-lock bolts for rigid, vibration-resistant connections

- Guide pins for precise alignment during module changes

- Tool-assisted swap process (10-15 minutes per module)

Electrical Integration

- Anderson Powerpole 45A connectors for industrial-grade power connections

- M12 Industrial CAN Bus connectors for real-time control communication

- EEPROM-based automatic module detection for plug-and-play functionality

Navigation & Safety

- Line following capabilities using IR or camera-based sensors

- Basic obstacle detection with ultrasonic/infrared sensors

- Dust-resistant mechanisms preventing fiber accumulation

- Low-speed operation optimized for safety in industrial environments

Implementation Strategy

We applied a hybrid Agile-Systems Engineering approach combining iterative development with structured validation:

Development Phases

| Phase | Deliverable | Timeline |

|---|---|---|

| Phase 1 | Business needs & system requirements | Weeks 1-2 |

| Phase 2 | Detailed design completion | Weeks 2-3 |

| Phase 3 | Sub-system manufacturing | Weeks 2-6 |

| Phase 4 | System integration & testing | Weeks 5-7 |

| Phase 5 | Fleet management integration | Weeks 7-9 |

Key Working Packages

- Drive System Development: Motors, gearboxes, wheels with dust protection

- Lifting System: Servo-driven mechanism with 80kg capacity

- Navigation System: CPU/microcontroller with line-following sensors

- Power Management: Battery system with wire harness and indicators

- Modular Platform: Standardized interfaces for future expansions

Cost Analysis

Our preliminary Bill of Materials achieved the target budget of ~2000€ of hardware costs per AGV, assuming a fleet of 50 units:

| System Category | Components | Cost (€) |

|---|---|---|

| Drive System | Motors, drivers, wheels | 375 |

| Lifting System | Servo, spindle, mechanism | 100 |

| Navigation | CPU, sensors, line module | 480 |

| Power & Signals | Battery, BMS, harness | 240 |

| Structure | Chassis, body, assembly | 780 |

| Modular Platform | Connectors, interfaces | 60 |

| Total Hardware | 2,185 € |

Fleet Management Experience

In parallel to AGV development, we've built fleet management systems for drive system manufacturers:

SEW Eurodrive: Commissioning Tool & Fleet Management

For SEW Eurodrive, a leading competitor in the drive and control market, we developed:

- Commissioning tool for rapid AGV deployment - Streamlined configuration and parameter setting for drive systems in intralogistics applications

- Fleet management software - Real-time monitoring and coordination of multiple AGVs, optimizing traffic flow and task allocation

- Performance analytics - KPI tracking for AGV utilization, battery life, and throughput

This experience with SEW demonstrates our deep understanding of the drive and control market that Bosch Rexroth operates in. We know:

- How drive manufacturers position their products in intralogistics

- The integration challenges between drives and fleet management systems

- What OEMs need to successfully deploy AGVs with specific drive systems

- Competitive landscape and differentiators in the drive and control space

Application at Bosch Rexroth

This AGV reference implementation demonstrates how Bosch Rexroth's drive and control technology enables cost-effective automation for intralogistics:

- Precision motion control - Bosch Rexroth's drive systems provide the accurate positioning and smooth motion control critical for automated material handling

- Scalable control architecture - Integration with ctrlX AUTOMATION platform enables fleet management and Industry 4.0 connectivity

- Reference implementation - Demonstrates what's possible with Bosch Rexroth's drive technology to OEMs and system integrators

- Rapid prototyping capability - Motius can quickly develop custom AGV solutions showcasing Bosch Rexroth's products in customer-specific applications

For Bosch Rexroth's customers developing their own AGV solutions, this demonstrates: - How Bosch Rexroth's drives enable precise control in cost-effective platforms - Integration patterns with fleet management systems - Modular approach allowing customization for different industries - European-engineered solutions meeting local standards and support requirements

This positions Bosch Rexroth not just as a component supplier, but as an enabler of complete automation solutions for intralogistics applications.